AHCT GROUP NEWS

PLA - Walmart and others are going green with "biodegradable" packaging made from corn.

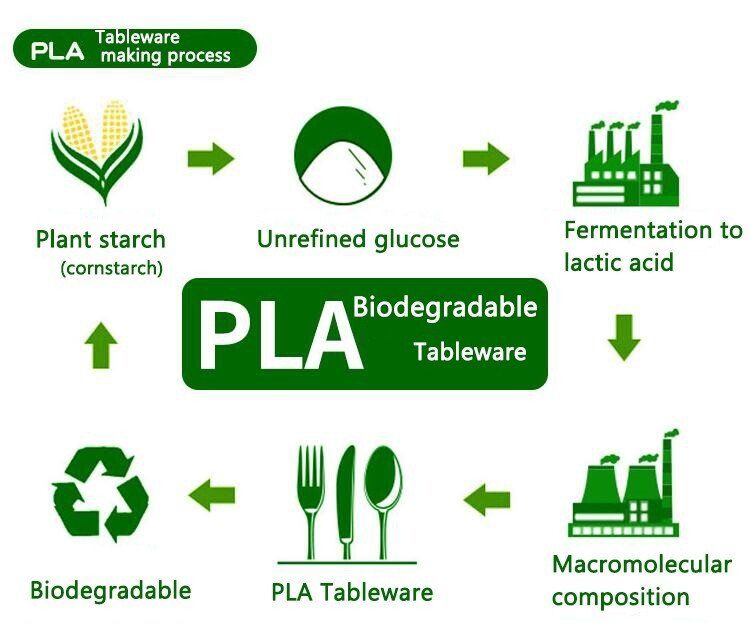

PLA resins are made into containers and packaging for food and consumer products. It's made from renewable resources, which means it has a big political and environmental advantage over traditional plastic packaging, which in the US uses an estimated 200,000 barrels of oil a day. In addition, PLA is in principle compostable, which means it breaks down into harmless natural compounds under certain conditions. That could ease pressure on the country's growing number of landfills, where plastic already makes up 25 percent of landfills by volume. With oil prices so high, corn-based plastics are starting to look cheap.

Natural food suppliers such as Newman's Own Organics and Wild Oats have been quietly using some PLA products for several years, but the material got its biggest boost when Walmart, the world's largest retailer, announced last October that it would sell some PLA products. Produced in PLA containers. The move is part of the company's efforts to counter criticism that it is not responsible for the environment. "Moving towards zero waste is one of our three environmental corporate goals," said Matt Kistler, vice president of private label and product development for the retailer. Walmart plans to use 114 million PLA containers annually, which company executives estimate will save 800,000 barrels of oil annually.

Food-Packing industry: PLA is Generally Recognized as Safe (GRAS) when using it to store food. Even though it can release lactic acid in contact with specific liquids, it was not found to have a concentration high enough to harm humans. Read more about PLA in the food industry and what you really need to know about it.

Healthcare and Medical industry: PLA plastic is biocompatible, meaning that it can be used for devices in the human body with minimum inflammation and infection. As a result, and given its attractive source, it has been employed in the production of biomedical and clinical applications , in bone fixation devices, such as screws, plates, surgical structure and meshes, and drug delivery systems. An amazing addition is the possibilities in tissue engineering. Its bio-compatibility and its ability to dissolve in the body show that it posses great promise in solving problems such as tissue loss and organ failure.

Structural applications: PLA material can be used in the construction industry as, for example, foam for insulation, fiber used in carpets, and in furnishing. However, given its properties and biological susceptibility, it has restricted applications in this industry.

Textile industry: Efforts in the plastic industry, aim to take bio-sourced PLA fiber to replace non-renewable polyester textiles. The advantages include breathability, lower weight, and recyclability, among others.

Cosmetics industry: consumer awareness of plastic pollution has driven industries as the cosmetic one to seek sustainable solutions that ensure product preservation.

PLA plastic is sustainable because it comes from renewable resources that absorb CO2 and convert it into glucose. This will later be processed to obtain a nearly carbon-free product. After PLA material is ready to be disposed of by the consumer, it can be biodegraded .

Barrett, A. and Barrett, V., 2022. All You Need To Know About PLA. [online] Bioplastics News. Available at: <https://bioplasticsnews.com/2019/07/02/all-you-need-to-know-about-pla/>